Winter weather may be mild in Louisiana compared to northern states, but even moderate temperature swings, increased moisture, and seasonal road conditions can take a toll on your truck’s axle and driveline components. At Consolidated Truck Parts & Service in Alexandria, LA, we’ve seen firsthand how post-winter wear can lead to vibrations, unusual noises, and performance issues that threaten your uptime. Whether you’re managing a municipal fleet or running your own logging operation, understanding what to inspect after winter can save you from costly breakdowns and keep your Class 8 truck running smoothly.

Why Winter Takes a Toll on Heavy-Duty Axles and Drivelines

Even in Central Louisiana, winter brings unique challenges for heavy-duty trucks. Temperature fluctuations cause metal components to contract and expand, stressing seals, joints, and bearings. Increased rainfall introduces moisture into your driveline system, accelerating rust and corrosion on exposed parts.

Winter stressors that damage your drivetrain:

- Moisture penetration through damaged boots or seals

- Cold-weather lubrication breakdown causing increased friction

- Corrosion on U-joints, CV joints, and driveshaft components

- Impact damage from road debris or uneven surfaces

- Bearing wear from thermal expansion and contraction

For vocational trucks operating in agriculture, timber, or municipal work around Alexandria, this seasonal stress is compounded by stop-and-go driving, heavy loads, and rough terrain typical of your daily routes.

The Hidden Damage Winter Leaves Behind

Here’s what most truckers don’t realize: winter damage often doesn’t show up until spring. Cold temperatures can mask developing problems. As things warm up, weakened components start failing under normal operating conditions.

A cracked seal might hold together in 40-degree weather, but once temperatures climb to 70 or 80 degrees, that same seal expands differently and starts leaking. A U-joint that’s lost its grease cap during winter might run quietly while cold but begins squeaking and binding as friction increases with warmer weather.

This is why post-winter inspections are critical. You’re not just checking for current problems but catching issues that winter created before they escalate into roadside breakdowns.

Common Post-Winter Problems and What to Watch For

Worn U-Joints and CV Joints

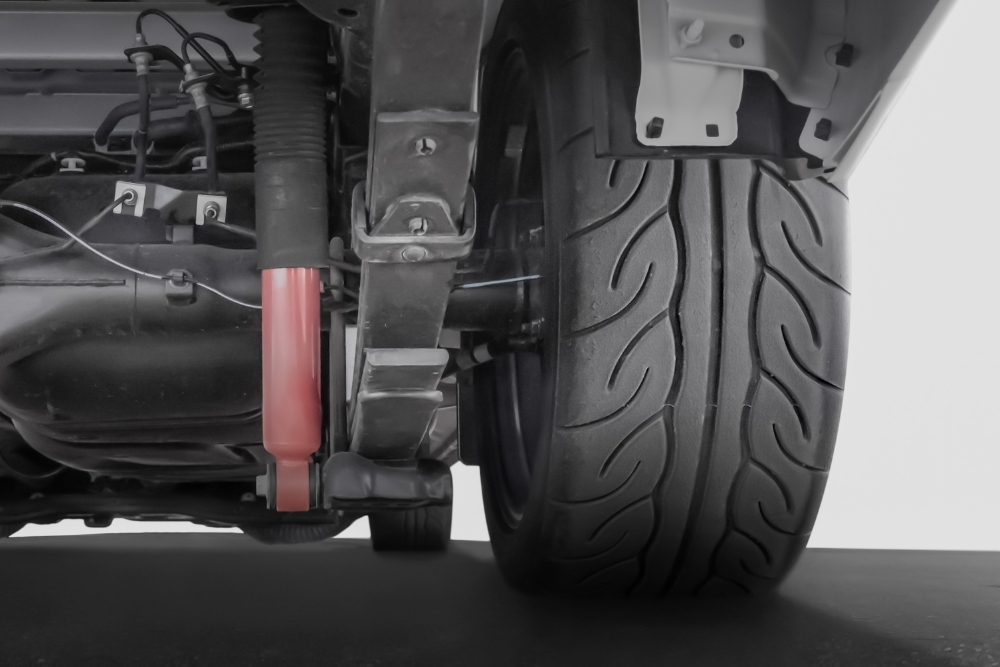

Universal joints connect sections of your driveshaft and allow it to flex as your suspension moves. Winter moisture and road debris corrode bearings, while temperature changes dry out lubrication.

Warning signs: Vibrations, clunking noises during acceleration, squeaking when starting from a stop.

Failing Wheel Bearings

When seals crack from cold weather or become contaminated with moisture, bearings lose lubrication and begin to grind.

Warning signs: Humming or growling noise that increases with speed, excessive wheel play, uneven tire wear.

Driveshaft Imbalance and Damage

Mud, road debris, or ice (for trucks traveling through colder regions) can accumulate on your driveshaft, creating an imbalance.

Warning signs: Vibrations at highway speeds that smooth out when you slow down.

Differential and Axle Seal Leaks

Cold weather causes differential seals to harden and crack, leading to gear oil leaks. Low fluid levels result in inadequate lubrication, accelerating wear on ring and pinion gears.

Warning signs: Oil spots under your truck, burning smell from the rear axle, low differential fluid levels.

Corroded Components

Exposed metal parts like yokes, flanges, and fasteners are vulnerable to corrosion from winter moisture. Rust can seize bolts and prevent proper torque transfer.

Warning signs: Visible rust on driveline components, difficulty removing bolts during service, reduced power transfer.

Experiencing any of these warning signs? Don’t wait for a breakdown. Contact Consolidated Truck Parts & Service at 3333 North Bolton Avenue, Alexandria, LA 71303, or call (318) 767-4287 to schedule your post-winter driveline inspection today.

The Real Cost of Ignoring Driveline Problems

Let’s talk about what happens when you put off that inspection. A worn U-joint that costs a few hundred dollars to replace can destroy your driveshaft when it fails, adding thousands to your repair bill. A leaking axle seal that goes unchecked will ruin your differential gears, turning a simple seal replacement into a complete differential rebuild.

For owner-operators and fleet managers, downtime is even more expensive than the repair itself. Every day your truck sits in the shop is a day you’re not generating revenue. Emergency repairs always cost more and take longer because shops need to order parts and juggle their schedule to accommodate you.

The smart move? Address issues early through preventive maintenance and post-winter inspections. It’s not just about saving money; it’s about staying in control of your operation instead of being controlled by unexpected breakdowns.

How Consolidated Truck Parts & Service Handles Alexandria Driveline Repair

When you bring your truck to our Alexandria location for axle or driveline concerns, you’re working with technicians who have the training, tools, and experience to diagnose and repair heavy-duty trucks correctly the first time.

Our diagnostic process:

- Detailed inspection: We use OE diagnostic software for all makes and models to identify issues that generic scan tools miss.

- Comprehensive component check: U-joints, CV joints, driveshaft balance, wheel bearings, axle seals, and differential fluid condition.

- Clear communication: Your service advisor contacts you with a full explanation of the issue, necessary repairs, and realistic timeline.

- Your approval: We never start work without your approval.

- Progress updates: We keep you informed throughout the repair process.

What sets us apart:

- OE diagnostic software for Freightliner, Peterbilt, Kenworth, Mack, International, and more

- Experienced technicians trained on Class 8 and heavy-duty truck systems

- Large parts inventory for faster repairs with less downtime

- 24/7 mobile service available for emergency breakdowns

- One-year warranty on parts and labor for units and transmissions

We maintain a large selection of parts for all makes and models, which means faster completion times than shops that need to order most components. For fleet managers and owner-operators around Alexandria, this translates to less downtime and a faster return to revenue-generating work.

Protecting Your Investment Year-Round

Post-winter repairs are important, but preventive maintenance is your best defense against costly breakdowns. At Consolidated Truck Parts & Service, we work with Alexandria truckers to develop customized maintenance schedules that fit specific operations.

Essential preventive checks include:

- Inspecting U-joints for play or corrosion

- Examining driveshaft boots and seals for damage

- Monitoring differential fluid levels and condition

- Checking wheel bearings for noise or excessive play

- Looking for rust or corrosion on exposed components

Our fleet services include scheduled inspections, fluid changes, and proactive component replacement before failures occur. We recommend addressing any vibrations, noises, or handling issues immediately rather than waiting to see if they worsen.

FAQs About Post-Winter Axle and Driveline Repair in Alexandria, LA

What are the signs of a bad axle?

Signs of a bad axle include vibrations while driving, clunking noises during acceleration or turning, visible grease leaks near the wheels, and uneven tire wear. If you experience any of these symptoms, bring your truck in for an inspection to prevent further damage.

What causes driveline vibrations after winter?

Driveline vibrations after winter are typically caused by imbalanced driveshafts from accumulated debris, worn U-joints, damaged CV joints, or bent shafts from impact damage. Cold weather can also cause lubrication breakdown, increasing friction and wear in driveline components.

How do I know if my truck has a broken U-joint?

A broken U-joint usually produces a loud clunking or squeaking noise when you accelerate, decelerate, or shift gears. You may also feel vibrations or notice difficulty in transferring power smoothly to the wheels, especially under load.

Where can I get truck axle repair in Alexandria, LA?

You can get professional truck axle repair at Consolidated Truck Parts & Service, located at 3333 North Bolton Avenue, Alexandria, LA 71303. Our experienced technicians use OE diagnostic software and stock parts for all makes and models to minimize your downtime.

How often should I have my driveline inspected?

For heavy-duty trucks in vocational use, you should have your driveline inspected at least twice a year or every 50,000 miles, whichever comes first. Post-winter inspections are especially important to catch moisture-related damage, corrosion, and seal failures before they lead to major repairs.

Schedule Your Post-Winter Inspection in Alexandria, LA Today

Don’t let winter wear turn into spring breakdowns. If you’ve noticed vibrations, unusual noises, or any warning signs we’ve discussed, schedule an inspection with Consolidated Truck Parts & Service. Our Alexandria team is ready to help you get back on the road safely and efficiently.

We provide honest, expert truck repair services to the Alexandria community and beyond. Our technicians stand by their work, and our service advisors treat you like family. We’re committed to doing what we say we’re going to do, keeping you informed every step of the way.

Schedule your appointment online, call our Alexandria team at (318) 767-4287, or visit us at 3333 North Bolton Avenue, Alexandria, LA 71303. We also serve Louisiana truck operators at our additional locations: