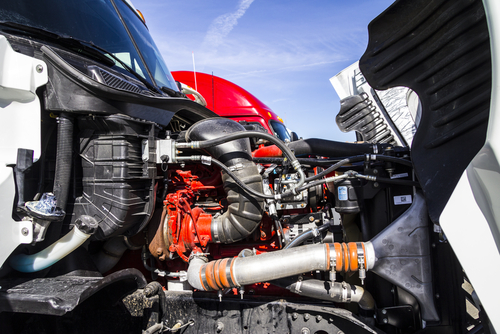

In Alexandria, the hum of diesel engines marks the rhythm of the transportation sector. These engines, powering everything from medium-duty pickups to heavy-duty commercial vehicles, are revered for their durability and strength. However, to maintain this reliability, regular maintenance is key, especially when it comes to the fuel system. At Consolidated Truck Parts & Service in Alexandria, LA, we specialize in servicing a wide range of diesel trucks, ensuring they run efficiently and effectively.

Components in the Diesel Fuel System

The diesel fuel system is the heart of your engine. It comprises several key components:

- Fuel Tank: Your truck may have one or more fuel tanks, depending on its type.

- Fuel Pump: This draws diesel from the tank(s) and delivers it to the fuel injectors.

- Fuel Filters: Diesel passes through two filters – the primary filter, located between the fuel tank and pump, and the secondary filter, situated between the fuel pump and engine.

- Fuel Lines: These can be metal or rubber hoses, designed specifically for diesel fuel, running from the tank to the fuel injectors.

- Fuel Injectors: Each cylinder typically has one fuel injector, which measures the required fuel amount. Some trucks may have throttle bodies with one or two injectors on top of the intake manifold.

Diesel Fuel System Maintenance In Alexandria, LA

Proper maintenance of the diesel fuel system is essential for optimal performance and fuel efficiency:

- Monthly Water Separator Checks: Keeping the diesel tank at least half-filled helps prevent moisture buildup, especially in trucks that don’t exhaust a full tank daily. For semi-drivers, it’s recommended to refuel before overnight stops or days off. Monitor your water separator monthly for condensation and other contaminants.

- Fuel Injectors: Over time, carbon deposits can accumulate, leading to injector clogs. At Consolidated Truc Parts & Service, we use high-quality fuel system cleaners to keep the injectors in pristine condition for optimal performance.

- Fuel Leaks: At our Alexandria, LA shop, we thoroughly inspect your fuel system for leaks during maintenance. Even a minor leak is hazardous and can lead to significant fuel loss. If you notice increased fuel consumption or smell diesel fuel, have it checked by an experienced technician immediately.

- Annual System Inspection: Conduct a comprehensive annual inspection of the entire fuel system to ensure everything is functioning correctly.

Resolve Your Fuel System Issues In Alexandria, LA with Consolidated Truck Parts & Service

Don’t let fuel system problems or any other truck issues slow you down. At Consolidated Truck Parts & Service, we’re more than just your go-to for all diesel engine needs. We offer comprehensive repair and maintenance services for a variety of truck brands and sizes, catering to both individual trucks and entire fleets. To ensure your truck is in top condition, we’re excited to offer a complimentary, no-obligation 40-point inspection—valued at $105—with every appointment. This thorough inspection is designed to identify any potential issues before they become major problems. Whether it’s setting up a regular maintenance schedule or handling necessary repairs, our expert team is here to provide the best care for your vehicle.

We offer convenient after-hours drop-off for those late-night shop visits.

Find us at these locations:

- 3333 North Bolton Ave., Alexandria LA 71303 ‣ Phone: (318) 767-4287

- 2604 Millhaven Road, Monroe LA 71203 ‣ Phone: (318) 325-1948

- 1000 Fisher Road, Many LA 71449 ‣ Phone: (318) 256-9683

Your diesel trucks are in good hands with Consolidated Truck Parts & Service, where we ensure they run as efficiently and reliably as the day you got them.